After proper heat treatment or cold drawing and hardening, carbon steel wire has high strength and hardness, high Elastic Limit and Fatigue limit (especially notch Fatigue limit), fair cutting performance, but poor welding performance and cold plastic deformation capacity.

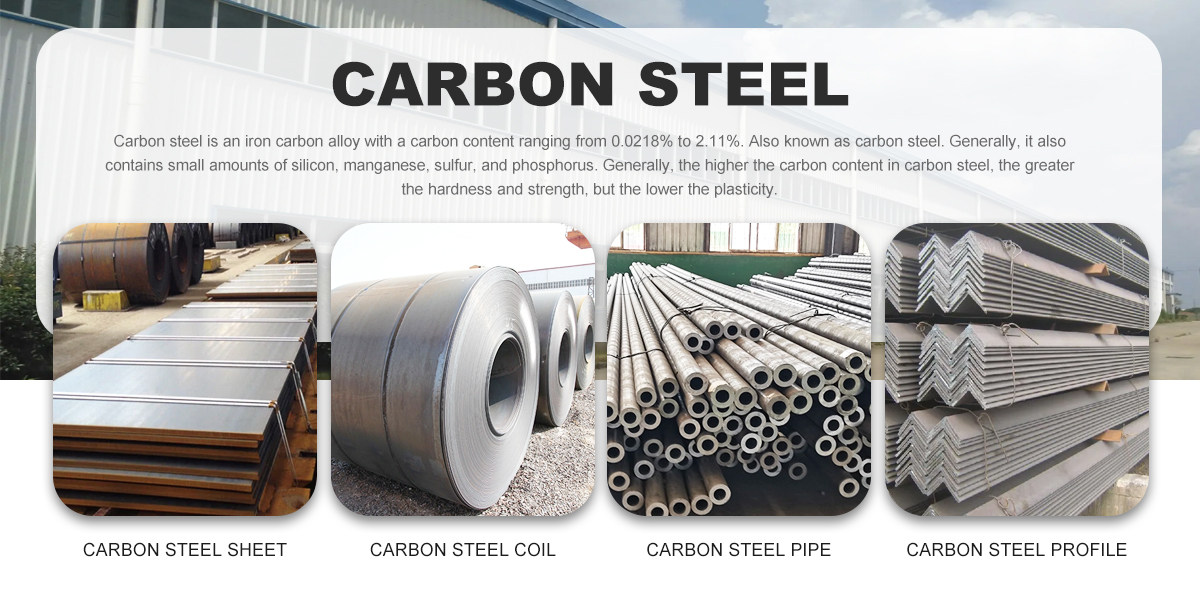

Carbon Steel Plates are made from an alloy of iron and carbon. Carbon steel plate is one of the most commonly used steel grades in the world. Alloy steels may contain a variety of elements, including chromium, nickel and vanadium. Steel may be defined as carbon steel when no minimum content of chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium, zirconium, or any other element is specified or required. Used to achieve alloying effects. We are specialists in supplying carbon steel plates, are leading carbon steel plate suppliers, and leading suppliers of carbon steel plates.

| Product Name | Carbon Steel Wire |

| Grade | SAE1006-1080,WA1010,Q195,SWRH32-37,SWRH42A-77A,SWRH42B-82B |

| Standard | GB standard,ASTM standard |

| Wire Gauge | 5.5mm-34mm |

| Dia tolerance | +/-0.3mm |

| Process | Hot rolled |

| Application | Mechanical&manufacture,Steel structure,Shipbuilding,Bridging,Automobile chassis |

| Lead Time | A.7 days if this goods is stock goods.B.20 days if this goods will be produced after order |

| Payment Terms | 30% T/T in advance as deposit,70% balance against the B/L copy or 100% irrevocable L/C at sight |

| Remark | Specific requirement of alloy grade,temper or specification can be discussed at your request |

| Grade | C | Si | Mn | P | S | Cu | Cr | Ni |

| Cor-ten A | 0.12 | 0.25-0.75 | 0.20-0.50 | 0.01-0.2 | 0.03 | 0.25-0.55 | 0.5-1.25 | 0.65 |

| Cor-ten B | 0.16 | 0.3-0.5 | 0.8-1.25 | 0.03 | 0.03 | 0.25-0.40 | 0.4-0.65 | ≤0.4 |

| SPA-H | 0.12 | 0.2-0.75 | 0.60 | 0.07-0.15 | 0.035 | 0.25-0.55 | 0.3-1.25 | 0.65 |

| 9CuPCrNi-A | 0.12 | 0.2-0.75 | 0.20-0.50 | 0.07-0.15 | 0.040 | 0.25-0.55 | 0.3-1.25 | 0.65 |

| Q235NH | 0.13 | 0.10-0.40 | 0.20-0.60 | 0.03 | 0.030 | 0.25-0.55 | 0.40-0.80 | 0.65 |

| Q295NH | 0.15 | 0.10-0.50 | 0.30-1.00 | 0.03 | 0.030 | 0.25-0.55 | 0.40-0.80 | 0.65 |

| Q355NH | 0.16 | 0.5 | 0.50-1.50 | 0.03 | 0.030 | 0.25-0.55 | 0.40-0.80 | 0.65 |

| Q415NH | 0.12 | 0.65 | 1.10 | 0.025 | 0.030 | 0.20-0.55 | 0.30-1.25 | 0.12-0.65 |

| Q460NH | 0.12 | 0.65 | 1.50 | 0.025 | 0.030 | 0.20-0.55 | 0.30-1.25 | 0.12-0.65 |

| Q500NH | 0.12 | 0.65 | 2.0 | 0.025 | 0.030 | 0.20-0.55 | 0.30-1.25 | 0.12-0.65 |

| Q550NH | 0.12 | 0.65 | 2.0 | 0.025 | 0.030 | 0.20-0.55 | 0.30-1.25 | 0.12-0.65 |

| Q265GNH | 0.12 | 0.10-0.40 | 0.20-0.50 | 0.07-0.12 | 0.020 | 0.2-0.45 | 0.30-0.65 | 0.25-0.50 |

| Q295GNH | 0.12 | 0.10-0.40 | 0.20-0.50 | 0.07-0.12 | 0.020 | 0.25-0.45 | 0.30-0.65 | 0.25-0.50 |

| Q310GNH | 0.12 | 0.25-0.75 | 0.20-0.50 | 0.07-0.12 | 0.020 | 0.25-0.55 | 0.30-1.25 | 0.65 |

| Q355GNH | 0.12 | 0.20-0.75 | 1.00 | 0.07-0.15 | 0.020 | 0.25-0.55 | 0.30-1.25 | 0.65 |

| Q345GNHL | 0.12 | 0.25-0.75 | 0.20-0.50 | 0.07-0.15 | 0.035 | 0.25-0.55 | 0.30-0.65 | 0.65 |

| Q295GQR2 | 0.12 | 0.10-0.40 | 0.20-0.50 | 0.06-0.12 | 0.020 | 0.25-0.45 | 0.30-0.65 | 0.25-0.5 |

| Q295GQR3 | 0.12 | 0.20-0.40 | 0.25-0.55 | 0.06-0.12 | 0.020 | 0.25-0.50 | --- | --- |

| Q345NQR2 | 0.12 | 0.25-0.75 | 0.20-0.50 | 0.06-0.12 | 0.020 | 0.25-0.50 | 0.3-1.25 | 0.12-0.65 |

| Q345NQR3 | 0.12 | 0.20-0.50 | 0.25-0.70 | 0.06-0.12 | 0.020 | 0.25-0.50 | --- | --- |

| Q400NQR1 | 0.12 | 0.75 | 1.10 | 0.025 | 0.008 | 0.25-0.55 | 0.3-1.25 | 0.12-0.65 |

| Q450NQR1 | 0.12 | 0.75 | 1.50 | 0.025 | 0.008 | 0.25-0.55 | 0.3-1.25 | 0.12-0.65 |

| Q500NQR1 | 0.12 | 0.75 | 2.00 | 0.025 | 0.008 | 0.25-0.55 | 0.3-1.25 | 0.12-0.65 |

| Q550NQR1 | 0.16 | 0.75 | 2.00 | 0.025 | 0.008 | 0.25-0.55 | 0.3-1.25 | 0.65 |

Standard export seaworthy packing.

3-20 days after confirming order, detail delivery data should be decided according toproduction season and order quantity.