Alloy coil is pearlitic heat-resistant steel with high thermal strength at high temperature( δ B ≥ 440MPa) and oxidation resistance, with certain hydrogen corrosion resistance.

| Prdouct Name | Alloy Coil&Strip |

| Thickness | 0.1-20 mm or as requirement |

| Width | 1000-6000 mm or as requirement |

| Length | Customized |

| Application | Auto, turbines, blades, powder and engines,etc |

| Feature | High corrosion resistance, low density, good thermal stability |

| Surface | Bright, Polished, Pickling, Acid cleaning, Sandblasting |

| Quality and test | Hardness test, Bending test, Hydrostatic etc. |

| Surface | Polished |

| Trade Term | FOB CIF EXW ,etc |

| Delivery | 7-25days or according to the product |

| Metal No: | Chemical Compostion(W%) | ||||||||

| C | Si | Cr | Mo | Mn | Fe | Cu | Ti | Ai | |

| Ni | Ni200Z | 1.00 | 2.00 | -- | -- | 1.50 | 3.00 | 1.25 | -- |

| -- | Bal. | Ni202Z | 0.15 | 3.30 | -- | -- | -- | -- | |

| -- | B2.3 | -- | Bal. | Ni205Z | 0.12 | 1.00 | 16.50 | 17.00 | |

| 1.00 | 6.50 | -- | W:4.50 | V:0.30 | Bal. | Ni206Z | 0.12 | 1.00 | |

| 1.00 | 28.00 | 1.00 | 5.00 | -- | -- | V:0.40 | Bal. | Ni207Z-NZ | |

| -- | 1.20 | 25.00 | 11.00 | -- | -- | -- | -- | -- | |

| Bal. | Ni219Z | -- | -- | 12.70 | 9.00 | -- | -- | Be 2.0 |

|

| 0.4 | 2 | Bal. | Ni222Z | -- | 0.50 | 22.00 | 13.00 | 0.70 | |

| 4.00 | -- | -- | Bal. | Ni230 | 0.30 | 1.50 | -- | ||

| -- | 1.50 | 3.50 | 30.00 | Nb:2.00 | -- | Bal. | Ni235 | 0.35 | |

| 2.00 | -- | -- | 1.50 | 3.50 | 30.00 | Nb:0.50 | -- | Bal. | Ni240Z |

| 0.35 | 1.25 | -- | -- | 1.50 | 3.50 | 29.50 | Nb:0.50 | -- | |

| Bal. | Ni250Z | 0.12 | 0.30 | -- | -- | 1.50 | 2.00 | 27-33 | |

| 0.60 | 3.00 | 68.00 | Ni255 | 0.05 | 0.50 | 12.50 | 3.00 | 1.50 | |

| 1.70 | bi:4.00 | sn:4.00 | -- | Bal. | Ni260Z | 0.40 | 3.00 | 15.5 | |

| -- | 1.50 | 11.00 | -- | -- | -- | Bal. | Ni262Z | 0.06 | |

| 1.00 | 21.5 | 9.5 | 1.00 | 5.00 | -- | Nb:4.00 | -- | Bal. | |

| Grade | Cr20Ni80 | Cr15Ni60 | Cr35Ni20 | Cr30Ni70 | Cr20Ni30 |

| Density(g/cm3) | 8.4 | 8.2 | 7.9 | 7.9 | 8.2 |

| Resistivity(Ωmm2/m) | 1.09 | 1.12 | 1.04 | 1.04 | 1.18 |

| Thermal Conductivity(Wmk) | 15 | 13 | 13 | 13 | 14 |

| Max temp(℃) | 1200 | 1150 | 1100 | 1100 | 1250 |

| Melting temp(℃) | 1400 | 1390 | 1390 | 1390 | 1380 |

| Magnetic | No | No | No | No | No |

| Specific electrica(Mpa) | 420 | 370 | 340 | 340 | 340 |

| Tensile strength(Map) | 650 | 600 | 600 | 650 | 600 |

| Elongation(%) | 30 | 35 | 35 | 35 | 30 |

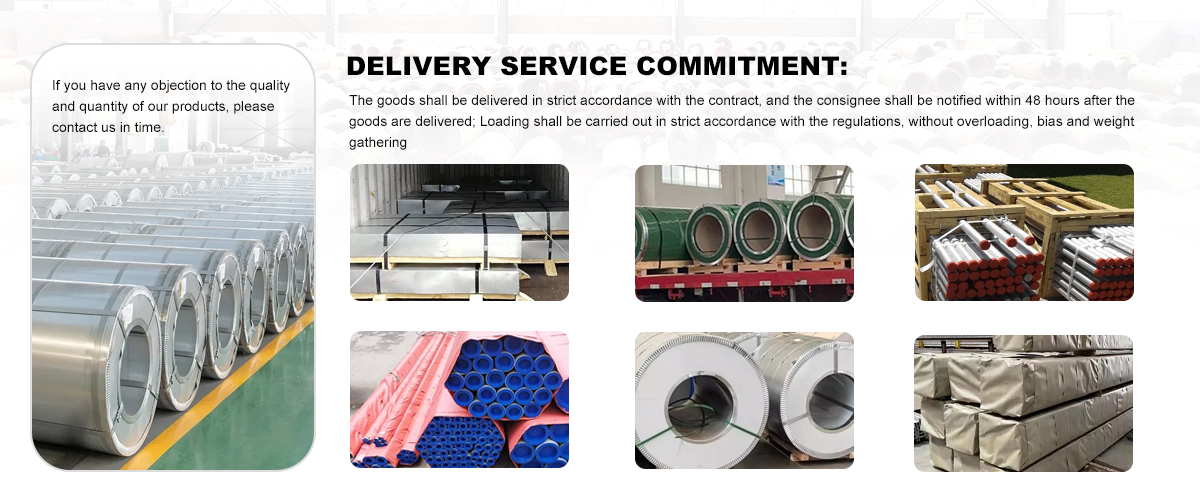

Standard export seaworthy packing.

3-20 days after confirming order, detail delivery data should be decided according toproduction season and order quantity.